Continuous Concrete Mixing Plant

Continuous Concrete Mixing Plant

Continuous concrete mixing plant is also called stabilized soil mixing plant, he is equipped with continuous mixer and batching machine, which is usually used to produce road base materials, such as compacted road base materials concrete, lime soil, stabilized soil, cement stabilized gravel, etc.

HuiHong continuous concrete mixing plant has the advantages of excellent performance, advanced technology, reasonable structure, reliable operation, easy to use, convenient maintenance, high efficiency, accurate proportioning and even mixing, etc. It is the basic material and ideal equipment for construction units.

HuiHong continuous concrete mixing plant is suitable for construction of highways, urban roads, airports, dams, quarry backfill, soil restoration and other substrate materials, which can use quicklime, slaked lime (10-15% water content), soil, sand, fly powder, etc. ash, cement, etc. to produce raw materials such as lime soil stabilized material, cement stabilized gravel and concrete base material.

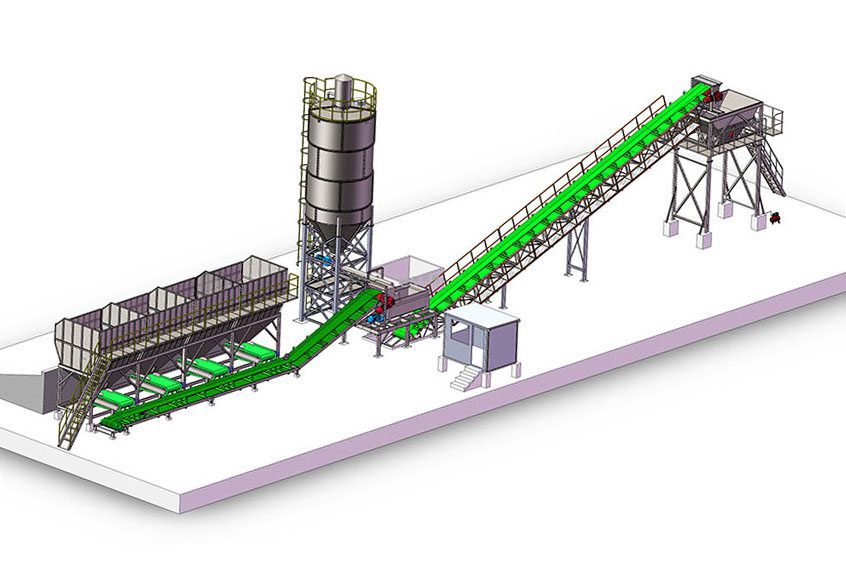

Stationary Continuous Mixing Plant

The stationary continuous mixing plant has a capacity of 200 to 600 tons per hour and is ideal for RCC plants (compaction roller mixing), paving slabs and stabilized soil production plants. The stationary continuous mixing plant consists of a continuous mixer, a dosing unit with multiple hoppers, a cement hopper and a dosing unit.

Mobile Continuous Mixing Plant

The mobile continuous mixing plant has a small footprint, is quick to install and easy to transport. It can be easily transferred from one project to another with a maximum capacity of 300 tons per hour. The mobile continuous mixing plant is used to produce all kinds of cement stabilized soil and cement stabilized gravel. It is the best equipment for all types of road projects, dam construction, quarry backfill, soil remediation and runway construction.

Continuous Concrete Mixing Plant Advantages

1. The continuous concrete mixing plant mainframe runs stably. The raw materials are discharged into the mixer separately in a longer period of time. And the whole loading process runs smoothly without intermittent or sudden loading operation.

2. The finished concrete is discharged into the mixer truck smoothly and continuously. While mixing the raw materials, the finished concrete is pushed to the discharge port and unloaded into the mixer truck automatically and continuously.

This mixing and unloading process is maintained for a long time without intermittent or gusty unloading operations.

3. Continuous concrete mixing plant covers a small area. The whole plant height is low. The plant reduces the large product hopper and intermediate aggregate storage hopper.

4. With less structure and short belt, the continuous concrete mixing plant runs more smoothly and has low maintenance cost.

5. Continuous concrete mixing plant adopts continuous mixer mixing and flow weighing for batching.

6. Continuous concrete mixing plant adopts smaller structure size to achieve maximum productivity.

Continuous Concrete Mixing Plant Components

The continuous concrete mixing plant is composed of five main systems.

- Gravel system: It consists of three feeding gravel hoppers (or two or four depending on different requirements) for gravel metering and feeding respectively. Each gravel hopper consists of aggregate bin, weighing unit, reduction box, feeding belt and auxiliary equipment.

- Powder system: The powder system consists of storage bin, butterfly valve, lifting screw, metering bin, disc feeder, etc. The powder bin includes main bin and sub-bin with single bin volume of 100T-300T. The main bin and sub-bin are equipped with automatic arch breaking device and material level signal indicating device. The powder storage bin is also equipped with dust removal system.

- Water and admixture system: Water and admixture system consists of admixture box, pool (or tank), pump station, water and admixture weighing hopper and pipeline.

- Transmission-mixing-storage system: The system consists of belt machine, mixer and mixer frame. Sand and gravel are loaded onto the belt by the batching machine and enter the mixer. Fly ash and cement are fed directly into the mixer through the disk feeder and the aggregate screw on the metering bin.

- Low voltage electrical and automatic control system: It consists of three main parts: power cabinet, sensors and control center.Camelway Machinery can supply complete continuous mixing plants in various sizes based on twin shaft continuous mixers.

Continuous Concrete Mixing Plant Workflow

- In the mixing process of continuous concrete mixing plant, after the machine is turned on, the batching system of each raw material is conveyed to the loading port of the mixer in order according to the distance to the loading port. Then all the materials are conveyed to the port synchronously.

- Pour the various raw materials into the mixer evenly according to the appropriate proportion.

- While mixing the raw materials, the mixer also pushes the raw materials forward. Therefore, when the raw material enters the mixer, the mixing process starts, and at the same time, the pushing process starts. Then during the pushing process, the material becomes finished concrete while pushing the material to the discharge port.

- When the preset amount of concrete is finished, the dosage system stops in the proper order of distance from the loading port.

- During the manufacturing process, the batching process, the loading process, the mixing/pushing process and the discharging process are carried out continuously.

Continuous Concrete Mixing Plant Parameter

| Model/Parameter/Project | WBZ200 | WBZ300 | WBZ400 | WBZ500 | WBZ600 |

| Rated Productivity | 200T/h | 300T/h | 400T/h | 500T/h | 600T/h |

| Size Of Aggregate | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

| Warehouse Inventory Of Aggregate | 3×4.5m3 | 3×6m3 | 4×6m3 | 4×8m3 | 4×10m3 |

| Warehouse Inventory Of Mixed Material | 6m3 | 6m3 | 6m3 | 6m3 | 6m3 |

| Accuracy Of Aggregate Measurement Scope(kg)/Accuracy | <±2% | <±2% | <±2% | <±2% | <±2% |

| Accuracy Of Water Measurement Scope(kg)/Accuracy | <±1%-±2% | <±1%-±2% | <±1%-±2% | <±1%-±2% | <±1%-±2% |

| Accuracy Of Cement Measurement Scope(kg)/Accuracy | <±1% | <±1% | <±1% | <±1% | <±1% |

| Mixer Speed | 63.2r/min | 63.2r/min | 63.2r/min | 65r/min | 65r/min |

| Total Power | 75kw | 102.7kw | 120.2kw | 155.5kw | 175.5kw |

| Weight | 30000kg | 39000kg | 41000kg | 51000kg | 63000kg |