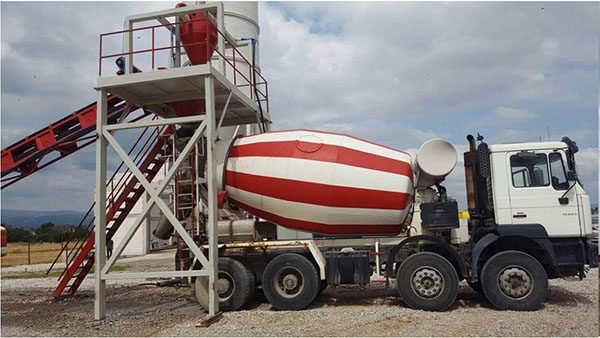

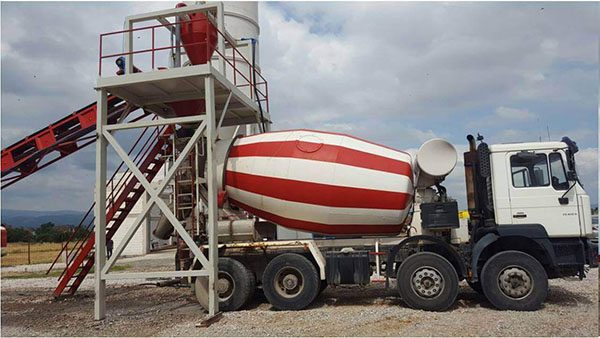

Planta dosificadora de hormigón de mezcla seca

Planta dosificadora de hormigón de mezcla seca

Tipos de concreto para diferentes procesos de producción

Hay dos tipos principales de plantas de concreto y están disponibles en cuatro combinaciones para diferentes procesos de producción..

- Mezcla seca plantas de lotes de concreto

- Planta de lotes de concreto de mezcla húmeda

- Planta de lotes de hormigón semi-mojado

- Plantas de lotes de concreto combinados

Es importante elegir la planta de mezcla de concreto adecuada de acuerdo con las características del edificio a construir y las instalaciones de tráfico. Desde este punto de vista, La diferencia entre una planta de concreto de mezcla seca y una planta de concreto de mezcla húmeda no es solo una mezcla húmeda o una mezcla seca, Pero hay otras diferencias importantes. Una planta de mezcla de concreto de mezcla seca es un tipo especial de equipo utilizado para mezclar concreto en comparación con otras plantas de mezcla. La planta de mezcla de concreto de mezcla seca es más eficiente, pero debe combinarse con un camión mezclador para mezclar concreto.

Diferencia entre la planta de mezcla de concreto de mezcla seca y la planta de mezcla de concreto húmedo

Una planta de mezcla de concreto de mezcla seca, También conocido como planta de mezcla de concreto seco, alimenta arena, grava y cemento a través de una planta de mezcla digital o manual. Todas las materias primas se descargan en un tanque inclinado en un camión. Al mismo tiempo, el agua se pesa o se mide volumétricamente y se descarga en el camión mezclador a través del mismo tanque de dosificación. Finalmente, Todos los materiales son mezclados y transportados al sitio.

Las plantas de concreto húmedo usan una batidora de concreto para mezclar todos los componentes anteriores (incluyendo agua) en una ubicación central, y el concreto se mezcla en el camino al sitio para evitar la configuración (Usando una batidora o un camión listo para mezclar).

Como plantas de concreto móvil y estacionaria, Las plantas de concreto seco consisten en un silo de cemento, sistema de alimentación, sistema de control, sistema de pesaje y sistema de mezcla. Los silos de cemento se utilizan para recolectar y suministrar materias primas como cemento, arena y cenizas volantes según las necesidades de producción. El sistema de alimentación es el puente entre los agregados y el sistema de mezcla. La precisión del sistema de pesaje determina la cantidad de materiales mixtos y, por lo tanto, tiene un gran impacto en la calidad del concreto mixto. El sistema de mezcla solo mezcla materiales sin agua. Por lo tanto, El camión mezclador es muy importante para transportar y mezclar el concreto. El sistema de control es el corazón de toda la planta. Los trabajadores pueden usar la planta de concreto en la sala de control para la automatización completa.

La mezcla en seco es diferente del equipo de mezcla húmeda. Las mezclas húmedas que incluyen una batidora de concreto central, mientras que las mezclas secas pueden proporcionar una mezcla más consistente en menos tiempo. Las plantas de lotes secos generalmente ven más variación en la desviación estándar de la resistencia de la rotura, así como la variación en diferentes cargas porque el cemento, La piedra y otras mezclas se pueden mezclar sistemáticamente que las mezclas húmedas. Algunas plantas de lotes de concreto combinan características de mezcla húmeda y seca para aplicaciones adicionales.

Ventajas de plantas de lotes de concreto de mezcla seca

- Mayor capacidad y menor consumo de energía porque el concreto se puede mezclar sin agua

- La cooperación entre la planta de mezcla en seco y el camión mezclador aumenta la productividad y ahorra tiempo.

- El concreto recién mezclado se puede usar cuando el camión mezclador llega al sitio de construcción.

- Reduce el tiempo de construcción y aumenta la productividad.

- Consume menos potencia en comparación con una planta de mezcla húmeda.

- Costos operativos relativamente bajos para plantas de concreto de mezcla seca

- Permite una mezcla más eficiente de concreto.

- Puede requerir menos tiempo de mantenimiento en comparación con las plantas de mezcla húmeda

- Como otras plantas de mezcla (p.ej. Plantas de mezcla de concreto móvil y estacionaria), La planta de mezcla de concreto seca está automatizada.

- Es ideal para fabricantes de plantas de concreto seco si el sitio es largo. El camión mezclador puede mantener una secuencia de rotación a medida que viaja al sitio de trabajo, Evitar la manipulación y el endurecimiento del concreto de la mezcla y garantizar la frescura del material.

- La vegetación de concreto de lotes secos es un equipo de producción de concreto moderno popular que continúa ayudando significativamente en el crecimiento y el desarrollo de las carreteras modernas, puentes y varios proyectos de construcción de concreto.

Flujo de trabajo de la planta de mezcla de concreto de mezcla seca

La planta de mezcla de concreto de mezcla seca es un tipo de planta especial de mezcla de concreto, que se utiliza principalmente en proyectos con bajos requisitos para la calidad del concreto y las largas distancias. En comparación con la planta de mezcla de concreto de mezcla húmeda ordinaria, La planta de mezcla de concreto de mezcla seca no está equipada con una batidora central y se mezcla con un camión cisterna durante el transporte. Cuando funciona la planta de mezcla de concreto seco, Los sistemas alimentan a los agregados pesados, cemento y cenizas volantes en la tolva de almacenamiento, y luego los materiales se cargan en el tanque de transporte a través de la tolva de almacenamiento. Próximo, El usuario lo carga en el camión cisterna de transporte junto con agua y otros aditivos. El camión cisterna de transporte controla la rotación del tanque a una velocidad razonable para lograr el propósito de mezcla.

Planta de mezcla de concreto de mezcla seca en venta

La planta de mezcla de concreto de mezcla seca es simple en estructura, fácil de operar y tiene muchas ventajas, como la buena calidad.. Cuando necesite tipo de mezcla seca, No necesitas mezclador, Más ahorrar tiempo y dinero. ¿Qué es mas?, Podemos garantizar la calidad de nuestros productos. En breve, Podemos proporcionar modelos de mezcla seca y modelos de mezcla húmeda para nuestros clientes.. Para diferentes tipos, Utilizamos diseño estándar y materiales especiales de acuerdo con los requisitos.. Podemos personalizar varias maquinaria y equipo para una planta de mezcla de concreto de alta calidad. Si necesita el que desea comprar, Por favor contáctenos lo antes posible. Daremos un gran descuento y un precio razonable.